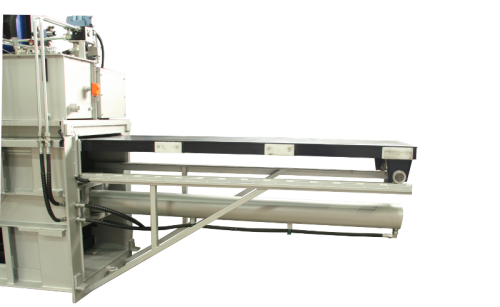

Waste balers type PBPe500-o

series 1100x780

Technical specification

Number of chambers:

single

Number of strappings:

4

Charging hole:

1500 x 720 mm

Bale launch:

automatic, complete

Max. pressure:

500kN (50 ton)

Supply:

400/50 [V/Hz]

Unit pressure:

5,82 kg/cm2

Socket:

400/63A

Bale dimensions:

1100 x 780 x 600-1500 mm

Fuse protection:

32C

Bale weight:

ok. 200 - 600 kg

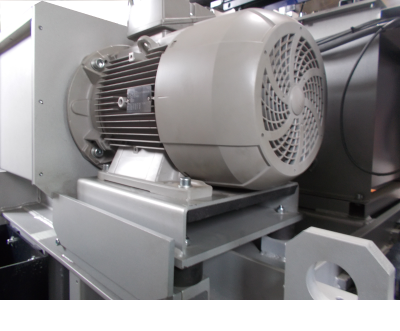

Engine power:

15 kW

Productivity:

ca. 2-6 bale/h.

Weight:

8000 kg

Loading:

top

Bale tying:

manual

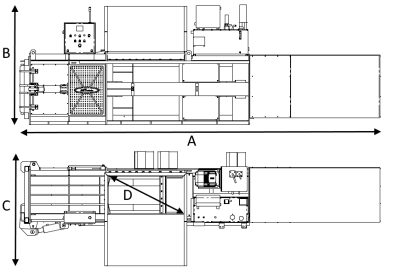

Dimension

Legend

[mm]

A

Length

7150

B

Height

2300

C

Width

1965

D

Filling inlet

1500 x 720

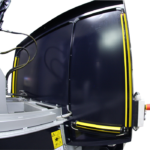

Advantages of the machine

Safety - is our priority. You can meet a lot of

machines on the market, which, despite the declaration of conformity and

CE marking do not comply with the basic assumptions of European Safety

Standards. Below you may find a few basic safety elements used in our

machines:

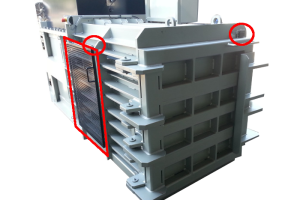

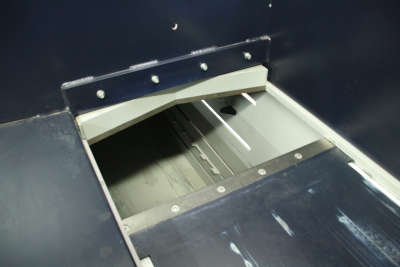

Protection of tying zone

Protection of tying zone

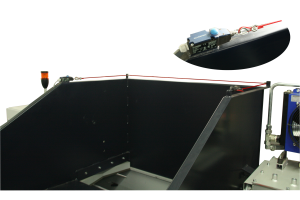

Protection of feeding zone

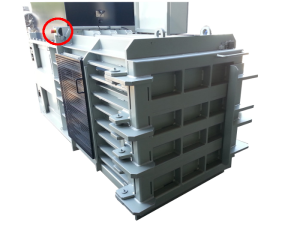

STOP switches

Security module SCHMERSALL

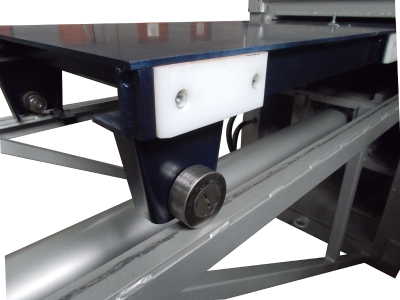

The moving of the pressing plate is kept extremely rigid and straight. The hydraulic cylinder does not take the bending forces from the pressing plate, which could lead to its damage. These forces are taken over by special plastic guides which are tailored to the corners of the chamber. The guides are made from specially chosen plastic, which is characterized by very high resistance to abrasion. Therefore, these elements are extremely durable. This avoids the need to control the tilt of the pressing plate. Because of all this you can easily exploit our machines, even for very demanding materials, without worrying of an improperly use of the machine. The steel construction of our machines is designed to withstand loads far in excess of the rated load for the different models (this is why our machines have a generally bigger own mass compared to the competition).

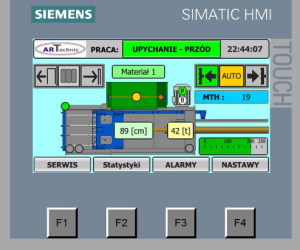

Controller SIEMENS S7

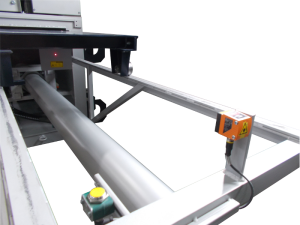

Solidne mocowanie noży odcinających nadmiar surowca

Laserowy czujnik długości beli

Hydraulicznie zamykana przeciwpłyta

Okna rewizyjne umożliwiające łatwą regulację płyty prasującej

Profile ślizgowe i rolki dla stabilizacji zasłony zasypu

Grzałka oleju z termostatem umożliwijąca pracę w każdych warunkach atmosferycznych

Zasilacz został wygłuszony dla lepszego komfortu pracy

Płyta prasująca w pełni wypycha gotową belkę

- A system to prevent the decompressing of material after subsequent cycles of work.

- Possibilty to bind the packages (bales) with all commonly used materials like a polyester tape, twine or steel wire

- The possibility of producing specified machines concerning the customer’s request e.g. changes in the stroke of the pressing plate, changes in the loading hole, changes in the size of the bale, etc.

- Possibility to choose the version of the controller, and to choose additional options, depending on individual needs

- Unmanned and durable hydraulic system

- No hidden costs of operating the machine

Steering

Steering x (EXTRA)

- Controller SIEMENS S7

- Automatic digital steering of the work cycle

- Finished-bale signal

- Stepless maximum pressure regulation with 1 ton progression

- Stepless bale height regulation with 2 cm progression

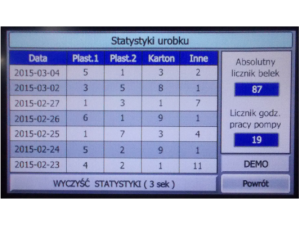

- Daily/weekly/monthly statistics – the readout of the number of finished bales with their weight estimation

- Different programs for different materials

- Possibility of regulating the length of time for which the pressing plate stays in the lower position

- the ability to connect the machine to the statArtechnic

Control Panel

Films

Tapes for bale tying

Specification:

Width [mm]

Endurance [mm]

Tape length in roll [mb]

19

725

250

6 (string)

590

220

Width [mm]

Endurance [daN]

Weight [kg]

3

<400

40