Waste balers type PBe180

series 1100

Technical specification

Number of chambers:

single

Number of strappings:

4

Charging hole:

1080 x 570 mm

Bale launch:

automatic

Max. pressure:

180kN (18 tons)

Supply:

400/50 [V/Hz]

Unit pressure:

2,34 kg/cm2

Socket:

400/16A

Bale dimensions:

1100 x 700 x 600-700 mm

Fuse protection:

10C

Bale weight:

ca. 200 - 250 kg

Engine power:

3 kW

Productivity:

ca. 2 bale/h.

Work cycle:

ca. 40 seconds

Loading:

frontal

Weight:

1400 kg

Bale tying:

manual

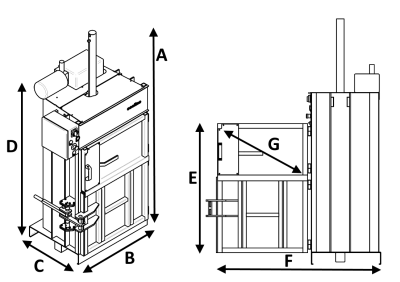

Dimension

Legend

[mm]

A

Height

2500

B

Width

1700

C

Depth

1050

D

Transport height

2000

E

Door height

1260

F

Depth with open door

2300

G

Filling inlet

1080 x 570

Advantages of the machine

- The moving of the pressing plate is kept extremely rigid and straight. The hydraulic cylinder does not take the bending forces from the pressing plate, which could lead to its damage. These forces are taken over by special plastic guides which are tailored to the corners of the chamber. The guides are made from specially chosen plastic, which is characterized by very high resistance to abrasion.Therefore, these elements are extremely durable. This avoids the need to control the tilt of the pressing plate. Because of all this you can easily exploit our machines, even for very demanding materials, without worrying of an improperly use of the machine.

- The steel construction of our machines is designed to withstand loads far in excess of the rated load for the different models (this is why our machines have a generally bigger own mass compared to the competition)

- A system to prevent the decompressing of material after subsequent cycles of work.

- Possibilty to bind the packages (bales) with all commonly used materials like a polyester tape, twine or steel wire

- The possibility of producing specified machines concerning the customer’s request e.g. changes in the stroke of the pressing plate, changes in the loading hole, changes in the size of the bale, etc.

- Possibility to choose the version of the controller, and to choose additional options, depending on individual needs

- Unmanned and durable hydraulic system

- No hidden costs of operating the machine

Steering

Steering p (PLUS)

- Controller PLC

- Automatic digital steering of the work cycle

- Finished-bale signal

Steering x (EXTRA)

- Controller PLC

- Automatic digital steering of the work cycle

- Finished-bale signal

- LCD display

- Stepless maximum pressure regulation with 1 ton progression

- Stepless bale height regulation with 2 cm progression

- Daily/weekly/monthly statistics – the readout of the number of finished bales with their weight estimation

- Different programs for different materials

- Possibility of regulating the length of time for which the pressing plate stays in the lower position

- the ability to connect the machine to the statArtechnic

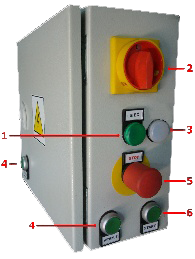

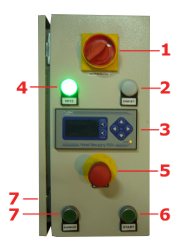

Control Panel p (PLUS)

- The green light “POWER” indicates a connection of the bale to power and that the main switch is turned ON

- Main switch with the possibility to lock in position “0” (prevents from an use of the machine by unauthorized persons)

- The white light “PACKET” indicates that the press has achieved the maximum filling

- Buttons “THROW-OFF”. Two-handed operation –controler for the bale ejector

- Emergency “STOP” switch

- Button “START” – starts the pressing process

Control Panel x (EXTRA)

- Main switch with the possibility to lock in position “0” (prevents from an use of the machine by unauthorized persons)

- The white light “PACKET” indicates that the press has achieved the maximum filling

- LCD and control panel

- The green light “POWER” indicates a connection of the bale to power and that the main switch is turned ON

- Emergency “STOP” switch

- Button “START” – starts the pressing process

- Buttons “THROW-OFF”. Two-handed operation – controler for the bale ejector

Film

Tapes for bale tying

Specification:

Width [mm]

Endurance [daN]

Tape length in roll [mb]

16

450

350

5 (string)

510

200